From Foam to Foam

In November 2003 the EPS – Loop project was launched by a consortium of eleven companies. This co-operation was based on the CreaSolv® Process and the main goal was the development and optimization of this recycling process for EPS waste. Additionally a concept for a cost efficient transport of EPS waste was be developed as well. The run-time of the project was 18 months and the total budget € 1.1 million.

The “EPS-Loop” was one of the few winners of the InnoNet - competition of the year2002, that was accepted by the German Federal Ministry for Economy and Work („Support of innovative networks“ – InnoNet) without any restrictions and supported with € 604.000.

Download:

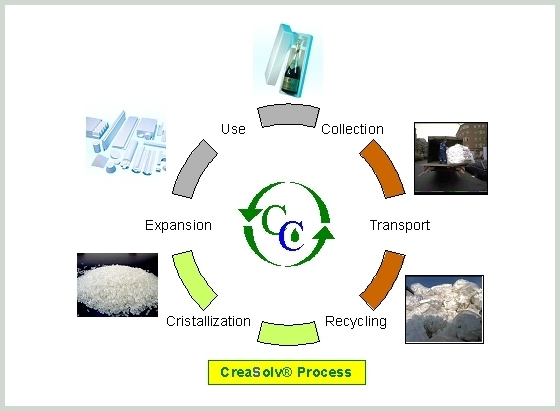

In July 2005 the project was successfully completed. In a pilot scale unit of Fraunhofer IVV it was demonstrated that the CreaSolv® Process recycles different EPS waste streams to re-expandable polystyrene. The EPS insulation sheets, produced out of it, behave like virgin material and are applicable without restrictions according to DIN 4108-10 test for flat and steep roofs, walls and floors without subsonic noise insulation. For recycling plants with annual capacities of 4 or 8.000 tons EBITDA margins of 50 – 60% were calculated and dependent on the capacity utilisation the investment is paid back within 2-5 years.

The results were summarized in a final report and presented to the public at the FAKUMA forum 2005 on 20 October 2005 in Friedrichshafen, Germany. Fakuma_EPS-loop presentation

In this project CreaSolv® PS was used, a proprietary formulation with high solvency power for polystyrene (PS), especially designed for fast volume reduction of expanded polystyrene (EPS). It is not classified according to the criteria of the European Union as laid down in Annex VI to 67/548/EEC (dangerous substance directive / Ordinance on Hazardous Materials).

Expanded polymers like polystyrene can be collected already dissolved in CreaSolv® PS, what offers higher volume reduction than the present systems. The dissolved polymer can be immediately processed and recycled in the CreaSolv® Process.

The InnoNet-Jury especially complemented the idea sketch with the utilization plan, that already included an efficient cost calculation that accompanied the project during ist entire duration.

Download: InnoNet News Nr. 18, Ausgabe Juni 2006

In 2007 the World patent WO/2003/035729 – „Recycling of waste expanded polystyrene foams to give products which may be re-expanded“ was granted.

The industry partners were not interested in a commercialization at this time because they had more attractive options available:

- EPS packaging waste can be regranulated and sold as 2nd grade polystyrene.

- According to the Packaging Waste Directive 2005/20/EC energy recovery (incineration) is considered as effective means of waste recovery.

- EPS insulation boards flame-retarded with Hexabromcyclododecan (HBCD) are not considered as "dangerous waste".

- EPS construction waste containing HBCD can be incinerated.

The situation only changed in May 2013 when the "Stockholm Convention on Organic Pollutants (POP-Convent) included HBCD in the POP List, that formally triggered a World-wide ban effective 26.11.2014. In the EU the HBCD ban starts on 21.08.2015, because the expiration date under REACH is set on this date.